Graphene in civil engineering

Contents |

[edit] Introduction

Scientists at the University of Manchester first isolated flakes of graphene in 2004, winning them a Nobel prize in physics 6 years later. The many superlative properties of the material have led to thousands of scientific publications and patents every year in this new and exciting area of research.

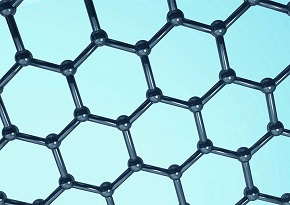

Graphene is a one-atom-thick honeycomb of carbon atoms with world-beating mechanical, thermal, optical and electrical properties. It has already been used for flexible electronics, energy storage, nanocomposites, sensors, liquid filtration and thermal management.

[edit] Construction applications

UK companies are now developing commercial applications of graphene for civil engineering. For example, Graphitene Ltd is currently developing thermally conductive cement grout materials containing graphene for geothermal wells, as well as cements with graphene admixtures that are mechanically stronger.

The company is also working on improving asphalt with graphene, both for more thermally resistant and durable roads, with increased elastic recovery and reduced cracking, and for fire-resistant bitumen roof materials.

Meanwhile, Haydale Composite Solutions Ltd has announced production of graphene-enhanced, electrically-conductive, carbon fibre reinforced, composite materials with improved resistance to damage from lightning strikes. This has already been incorporated into an aileron designed by Airbus and could soon be used for wind-turbine blades.

[edit] Supply chain concerns

However, while the future is bright for this 2D carbon material, it is not without challenges. One of the crucial barriers to real-world applications is lack of confidence in the supply chain.

It is common for companies which want to develop graphene-enabled products to struggle to find a reliable source of material from graphene suppliers. This is due to batch-to-batch variability, an issue that can be amplified by the fact that neither the supplier nor end-user really knows the physical or chemical properties of the material supplied.

The problem is because commercially available graphene, from the hundreds of suppliers world-wide, is typically a black powder or liquid containing flakes of one or a few layers graphene, as well as graphite. Measuring a statistically representative amount of nanoscale flakes for every part of every batch of material that can be produced on the tonne-scale is extremely difficult. Similarly, there are no standardised measurement procedures for doing this and so no well-defined quality control techniques exist.

[edit] New standard and guide

The issue is being addressed through work at the National Physical Laboratory (NPL), the UK's national measurement institute, which has developed the first international graphene standard on terminology within the International Organization for Standardization (ISO, 2017). This is an important first step in allowing different parts of the graphene supply chain to communicate what type of graphene they require.

Furthermore, we have now released a good practice guide entitled Characterisation of the structure of graphene in partnership with the National Graphene Institute at the University of Manchester, which will form the basis for future ISO measurement standards (NPL, 2017). This enables end-users to compare the properties of commercial graphene that have been measured in the same, reliable and accurate way.

It is hoped that through this work, more graphene-enabled products will soon come to market in many different application areas.

This article was originally published here by ICE on 15 January 2018. It was written by Andrew Pollard.

--The Institution of Civil Engineers

[edit] Related articles on Designing Buildings Wiki

Featured articles and news

Call for greater recognition of professional standards

Chartered bodies representing more than 1.5 million individuals have written to the UK Government.

Cutting carbon, cost and risk in estate management

Lessons from Cardiff Met’s “Halve the Half” initiative.

Inspiring the next generation to fulfil an electrified future

Technical Manager at ECA on the importance of engagement between industry and education.

Repairing historic stone and slate roofs

The need for a code of practice and technical advice note.

Environmental compliance; a checklist for 2026

Legislative changes, policy shifts, phased rollouts, and compliance updates to be aware of.

UKCW London to tackle sector’s most pressing issues

AI and skills development, ecology and the environment, policy and planning and more.

Managing building safety risks

Across an existing residential portfolio; a client's perspective.

ECA support for Gate Safe’s Safe School Gates Campaign.

Core construction skills explained

Preparing for a career in construction.

Retrofitting for resilience with the Leicester Resilience Hub

Community-serving facilities, enhanced as support and essential services for climate-related disruptions.

Some of the articles relating to water, here to browse. Any missing?

Recognisable Gothic characters, designed to dramatically spout water away from buildings.

A case study and a warning to would-be developers

Creating four dwellings... after half a century of doing this job, why, oh why, is it so difficult?

Reform of the fire engineering profession

Fire Engineers Advisory Panel: Authoritative Statement, reactions and next steps.

Restoration and renewal of the Palace of Westminster

A complex project of cultural significance from full decant to EMI, opportunities and a potential a way forward.

Apprenticeships and the responsibility we share

Perspectives from the CIOB President as National Apprentice Week comes to a close.